Our Main Fabric

Interlock, Fine Rib, Single Jersey in cotton 100% and cotton Lycra, Fleece, Pointelle fabrics , Thermal , Flat back , Heavy weight fabrics , Engineered Stripe fabric , Flat knit ,Plush, Pique, Transfer, Fashion Stitch and Weaving Fabrics for Casual wear.

We use the finest blend of cotton or polyester whether with or without lycra (Modal blend with cotton & specially Bio cotton organic with or without organic dyes )

All produced fabrics has to undergo rigid quality control and lab testing before dyeing ranging from 100 gm/m2 to 350 gm/m2

WORKING TEAM

Qualified knitting & production engineers, Accountants, Supervisors in readymade garments field Skilled Labors & Semi Skilled Labors under training

Our Products

For all ages & sexes

Polo Shirts, T-Shirts, Blouses ,Sweat Shirts, Mock & high necks Joggings, Pajamas, Night Gowns, Shorts and leggings, Panties, Slips & Singlet

For all ages & sexes

All our products pass through a quality control system for checking and controlling all production phases starting by Yarn selection, knitting, cutting, sewing, ironing and packing).

This system is managed by qualified engineers & supervisors to maintain quality according to international standards during and after production.

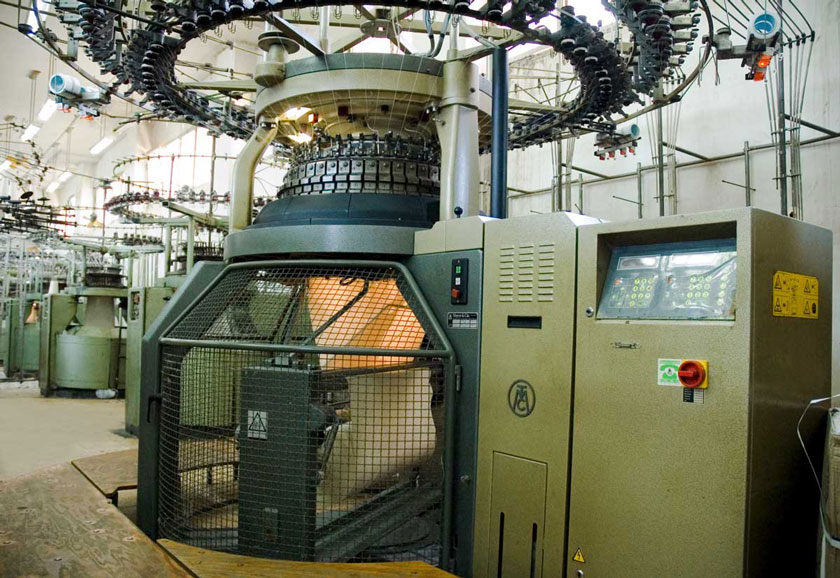

KNITTING

Sogic knitting machinery includes:

Our Capacity from 8 to 10 tones/day.

- 70 circular knitting M/Cs Mayer & Cie, Albi and Terrot, vignoni ranging from body size 9" up to 34" with gauge 16 up to 28 producing interlock, Jersey, Rib(1*1 , 2*2) ,Pique, Melton, Jacquar, lycra etc.

-1 winding and waxing Gilbos RCN model M/C with 60 spendles

-1 fabric inspection M/C

-1 OVJA ( Mayer Jacquart Knitting machines )

-body size rib machines gauge 18 from 9" to 19 "

-body size single jersey lycra machines gauge 28 from 12" to 20 "

-

body size single jersey lycra machines gauge 24 from 19" to 24 "

CUTTING

Complete automatic Gerber cutting system model 8.3 beside 4 manual cutting units, GGT ACCU-MARK Gerber patterns system (including Lectra - AM conversion software).

Cutting System components

A full automatic cutter with a capacity of 40 000 pcs/day

2body size tables with half automatic spreader

2open width tables with full automatic spreader

5 RIMOLDI laying m/c

Band knives

SEWING

Arafa Textile Confection Mill

It consists of six separate workshops, which include:

750 Industrial sewing m/cs mainly: RIMOLDI, PEGASUS, Pfaff, Durkopp, Juki, Yamato, Kingtex, Sibura and Union special. Covering all the sewing stitches needed for any under or outer wear with any added accessories

- 1 automatic Rimoldi polo line upto date following the latest technology trend consisting of 6 to 8 phases

- 14 Rotary and Steam presses for ironing

- 1 Caterpillar diesel generator 250K.V.A

- 2 Rotary Screw air compressors

- 2 Air Dryers

- Needle detector

EMBROIDERING

Section equipments:

1- A PFAFF electronic Embroidery m/c

2- BARUDAN automatic embroidery m/c

PRINTING

Our printing section contains

Three automatic machines in addition to hand printing tables provided with Tex-design software to separate colors to achieve the highest quality of printing according to OKO TEX & GOTS STANDARDS2- BARUDAN automatic embroidery m/c

CERTIFICATES

In addition to the Gots certificates and the Fair Trade certificate , Sogic is ISO 9001 certified, Sogic production is conforming to OEKO-TEX standards ,class I (starting from knitting till packaging) , Sogic has also Rich Law certificate & BSCI certificate.